LOTOP TECHNIQUE

LOTOP TECHNIQUE

The main task of the flux is to ensure required cleanliness of the bonded metals. In many cases volatile fluxes are an ideal alternative for traditional paste of powder fluxes. The use of volatile flux does not require special filler metals of torches of a special kind. Traditional gas mixtures are applied like oxy-propane, oxy-acetylene, oxy-methane.

Economic benefits of using volatile fluxes:

- reducing the brazing time by eliminating the activities associated with manual application of the flux,

- reduction to the workload and time required for actions associated with cleaning brazed joints,

- reducing costs associated with the recycling of post flux slag,

- possibility of using simpler, more cost effective cleaning methods,

- the cost of volatile flux in relation to the other materials (brazing filler metal, process gasses) used in the brazing process is quite low,

- large process efficiency

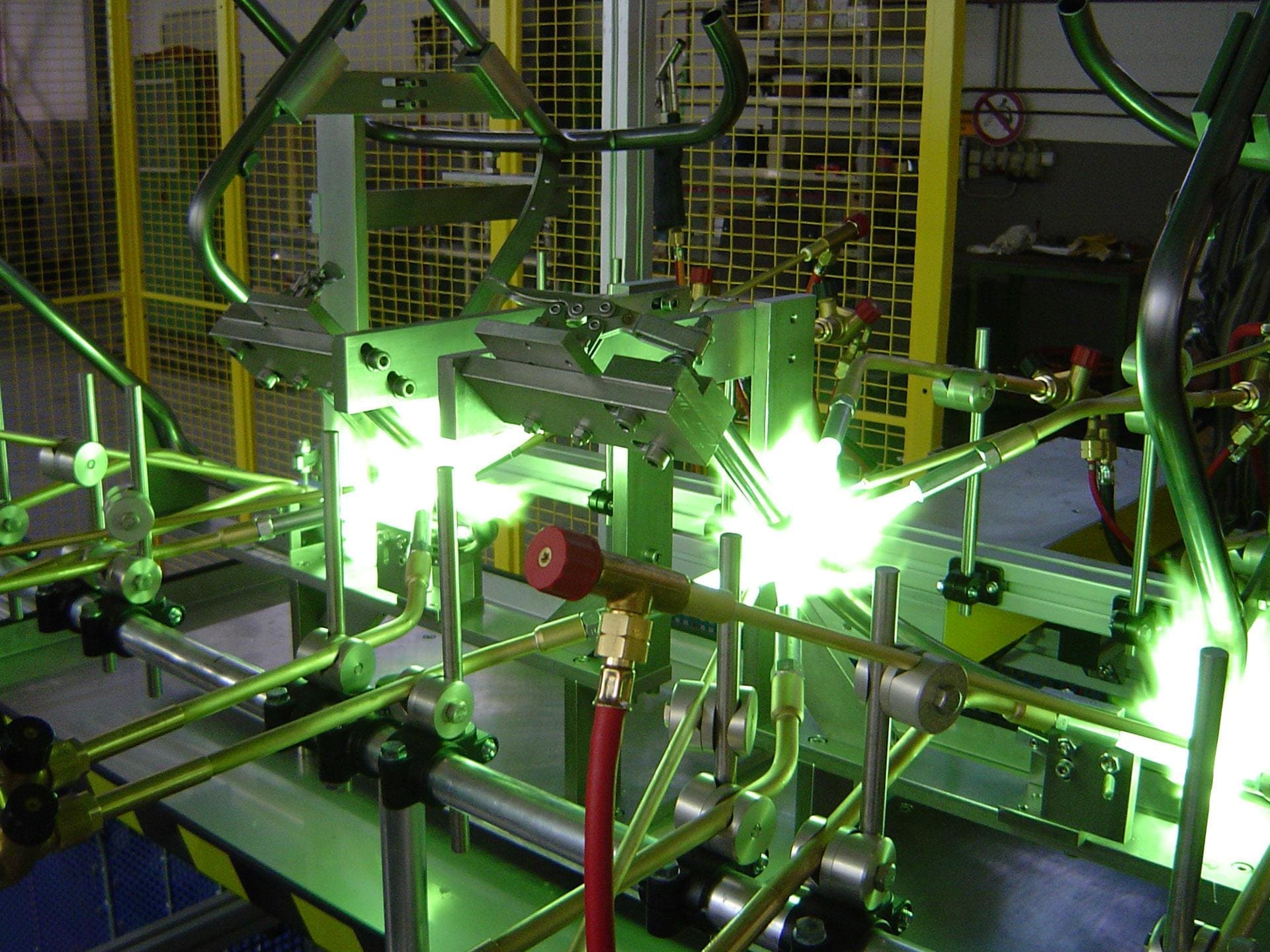

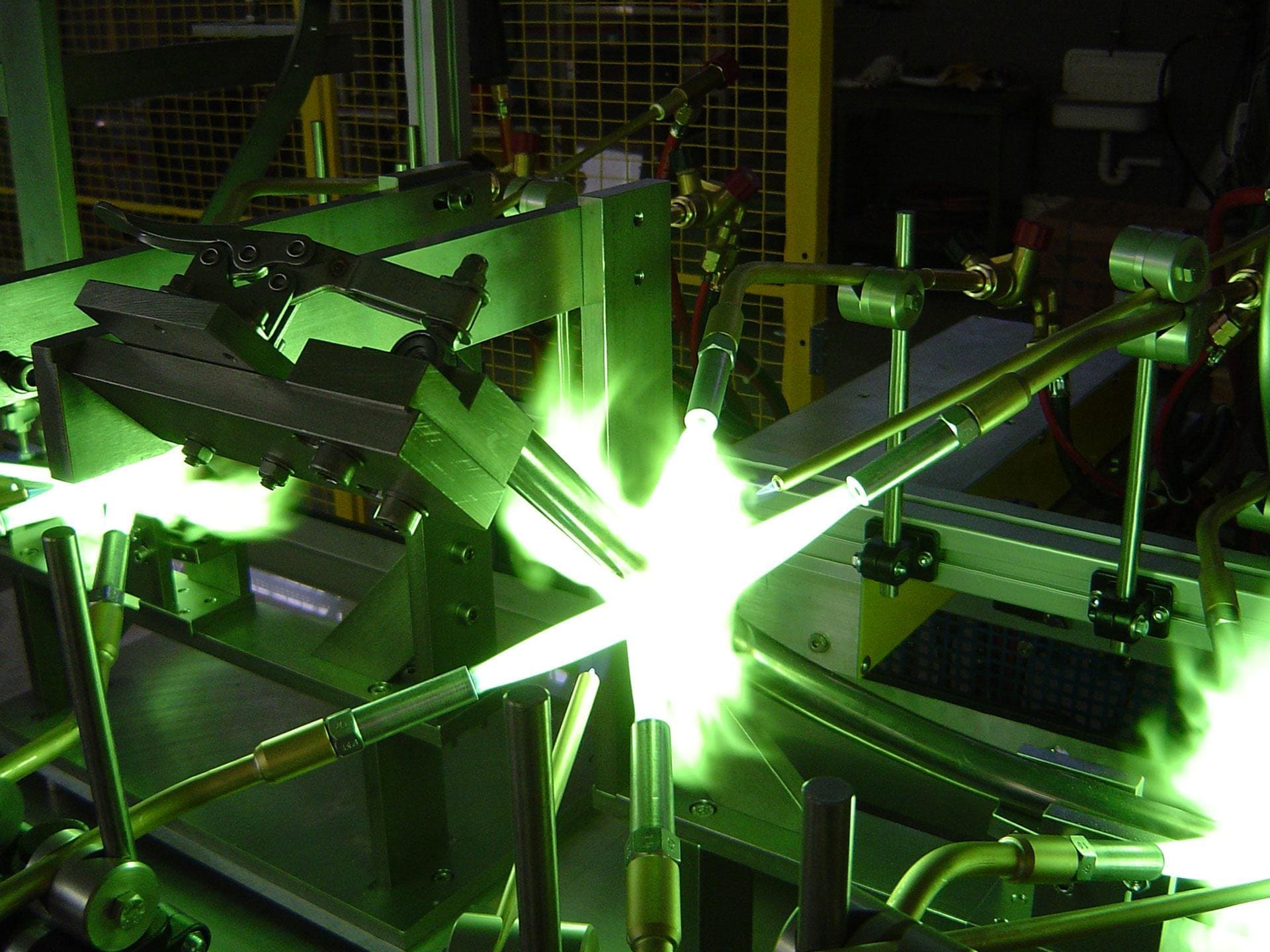

Application of volatile fluxes:

Due to the temperature range within which they are active ( 750° C – 1000° C) volatile fluxes are mainly used in brazing with copper-phosphorus, brass and new silver filler metals for the following bonds:

- steel-steel

- steel-copper

In the systems listed above, we are able to completely eliminate the use of traditional powder or paste fluxes.

Apart from the cases described above, volatile fluxes may also be used in brazing using copper-phosphorus and silver filler metals for the following types of bonds:

- copper-copper

- copper-brass

- brass-brass

- steel-copper

- steel-brass

- steel-steel

In bonds of this type, the volatile flux guarantees obtaining highly aesthetic and quality bonds.

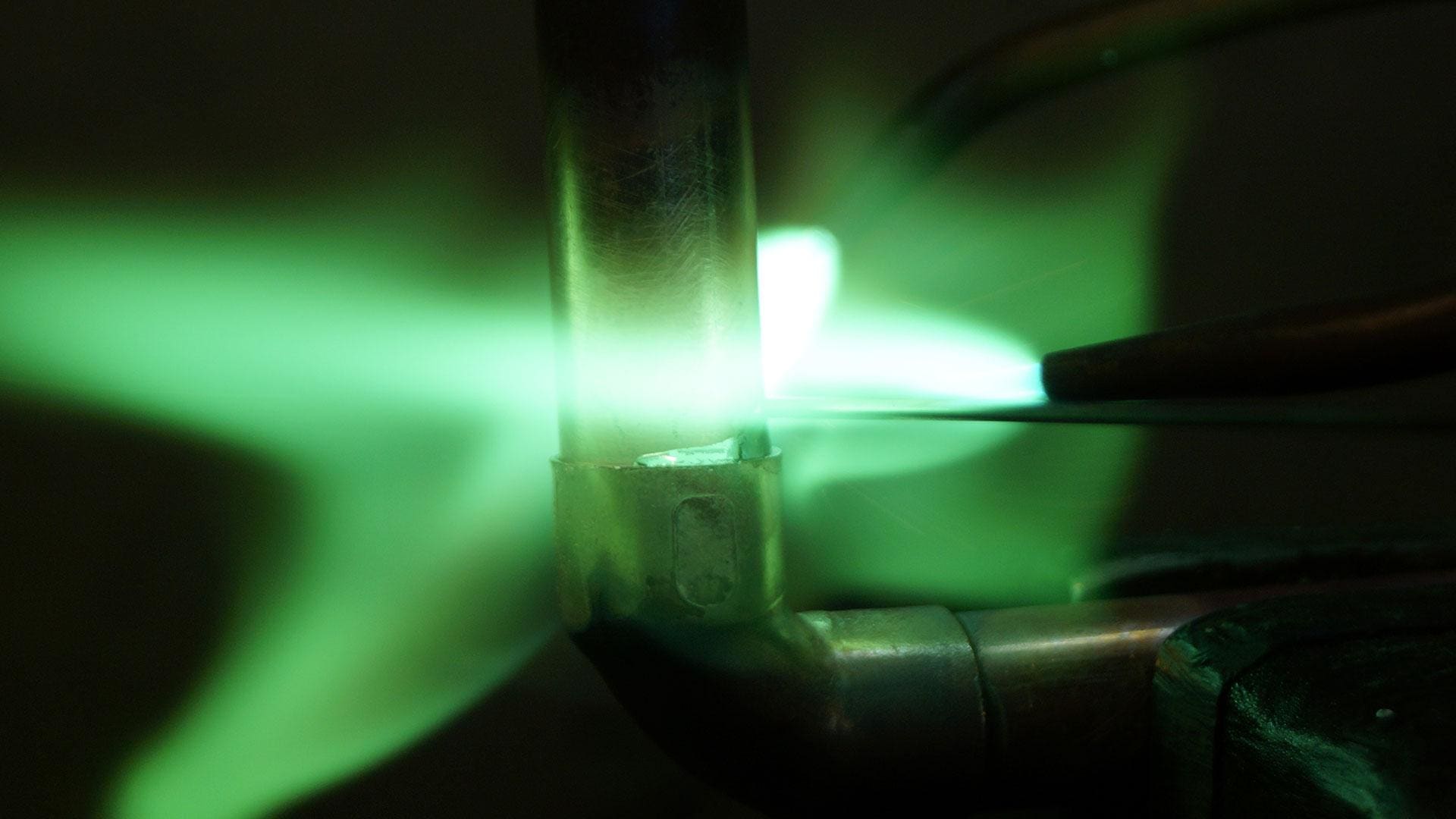

The flux is applied using a volatile flux dispenser

Lut-Spaw has been implementing the volatile flux technology for over 10 years. We have vast experience and excellent process knowledge at our disposal. Feel free to contact us and we will be more than happy to explain the advantages of using volatile flux in your production process